Why

Costa Rica

Key

Sectors

Knowledge-Intensive

Services

Delivery through multifunctional service centers

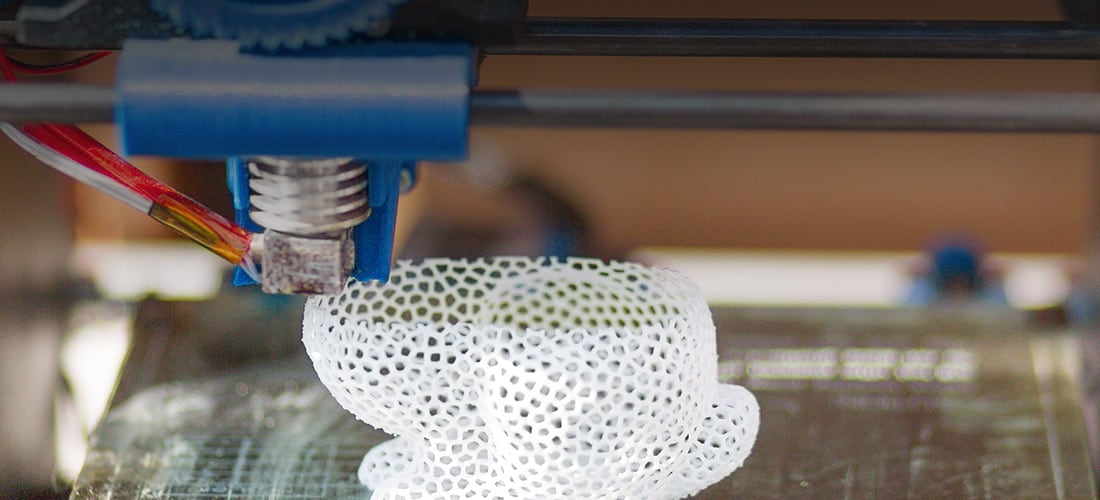

Smart

Manufacturing

Productivity through hi-tech and process sophistication